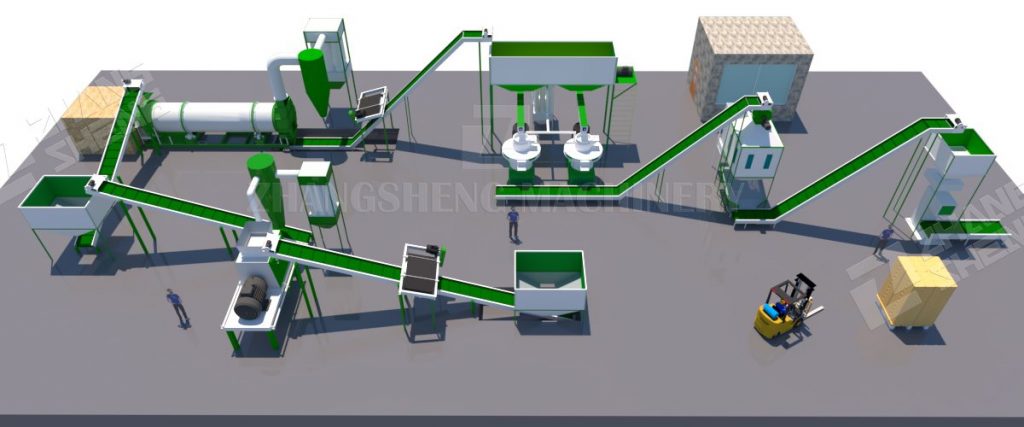

Sawdust pellet production line integrates all processes from raw materials to pellets, including crushing, drying, pellet making, cooling and packing, with an output of 1 to 10 tons per hour.

Sawdust pellet have high calorific value, less ash, low cost, small volume, easy transportation and no pollution. With the increasing shortage of coal, oil and other energy sources, the market demand for wood pellets is increasing, and the profits are considerable.

Promising Pellet Market & Sawdust Pellet Plant

Sawdust pellets have a high flammability value and can be used in home building small furnaces and in industry as a climate-neutral alternative to crude oil or natural gas.

Sawdust pellets are small in size and low in transportation costs. The raw materials is renewable, and you can save about half your fuel bills compared to petrol or natural gas. With more than 80% lower greenhouse gas emissions than coal, wood pellets are one of the most effective ways to meet renewable energy and carbon reduction goals.

From 2010 to 2025, the demand for industrial wood pellets will grow by an average of about 2.3 million tons per year. Between 2020 and 2021, global industrial pellet demand increased by 18.4%, while production increased by only 8.4%. The EU region and the UK, in particular, often run into pellet shortages under high energy costs. Therefore, the wood pellet production line is a promising and lucrative project.