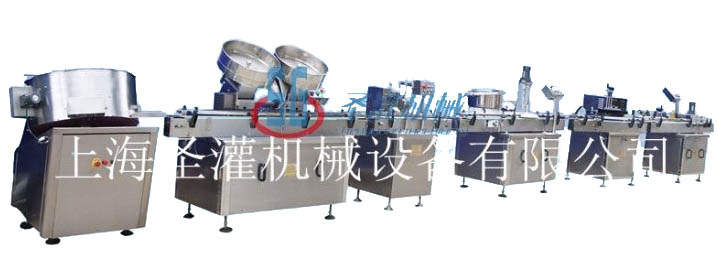

The production line consists of automatic bottle machine, automatic frequency conversion double-headed tablets (grain) machine, automatic variable-velocity plug-paper capping machine, electromagnetic induction aluminum foil sealing machine and vertical labeling machine. It is suitable for the whole process of counting, filling, stuffing, capping, labeling and labeling of tablets, pills, capsules and other special-shaped tablets in the pharmaceutical, food, and daily chemical industries. Reduce manual operations and achieve full automation. According to the needs of customers, dust cover can be purchased separately. The production line fully complies with the new GMP requirements.

Features:

The automatic bottle unscrambler uses the mechanical action for the bottle-handling process and does not need special care to save time and effort.

Frequency conversion screen-type digital film machine: low noise, stable falling sheet, correct counting, and speed can be adjusted by frequency conversion, and is equipped with a light control device without a bottle to stop falling, and an inverter-type plug and paper capping machine: Advanced design principle. Reasonable and compact structure, automatic paper feeding, scissors cut off, the speed of speed through the frequency control, no bottle automatic shutdown.

Aluminum foil sealing machine: with automatic elimination device without aluminum foil, adjustable speed within a certain range of adhesive labeling machine: when there is no bottle, the label will be automatically stopped and the batch number function will be automatically used.

Technical Parameters:

Applicable specifications 20-300ml

Production capacity 40-60 bottles/minute 100-120 bottles/minute

Power supply 380V/50Hz

Power 4.5 kw

The total length of the production line is 8000*900*1700mm